General Description

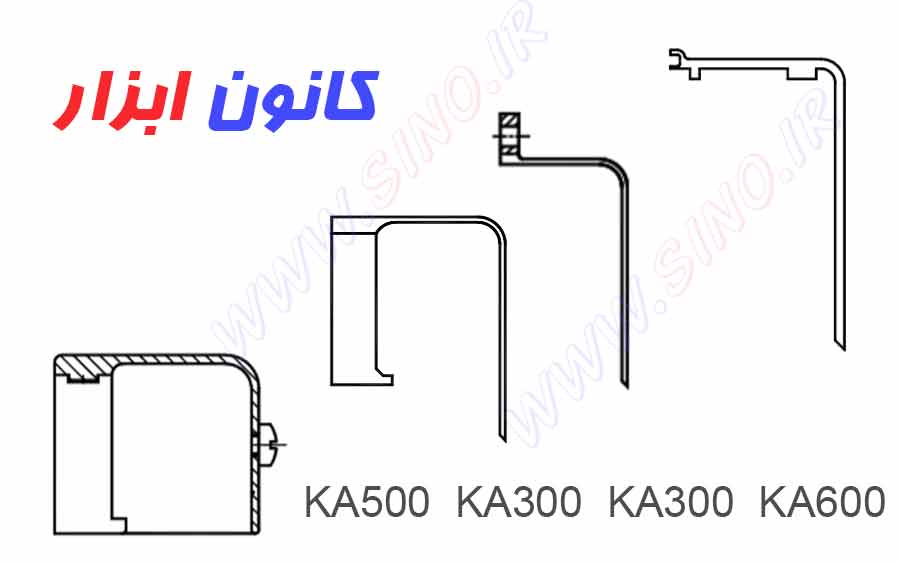

Many thanks for your use of this series of encoder. It is China’s most famous international brand. It will be your best bet once you choose it. SINO brand was initially founded in 1989. We are a professional factory dedicated to manufacture of encoder numerical display. By continuous modification and improvement through years of research and production, we have developed today’s KA series linear encoder. The KA series encoder under this manual includes KA-300, KA-600, KA-500 and KA-200, which can meet the requirements in different applications.

SINO KA300 LINEAR ENCODER

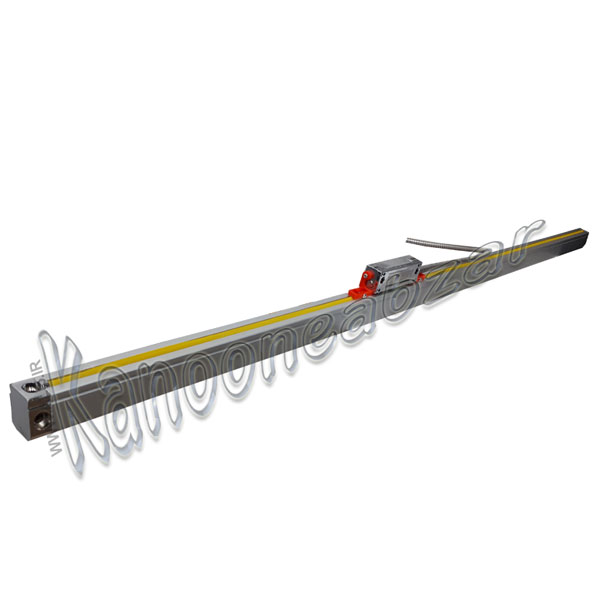

KA-300 is a type of encoder with wide applications. It features in optimal structure, good appearance and high rigidity, able to meet the needs of the majority of general machine users. The length is 70~1020mm.

SINO KA600 LINEAR ENCODER

KA-600 encoder, which is specifically designed for large machine tool, features in large size and good rigidity. Support may be added to any position of the encoder to enhance the rigidity and stability. The length is 1000~3000mm.

SINO KA500 LINEAR ENCODER

KA-500 is a mini-encoder specially designed for the machine tool which has a low installation size and small operation space. It can meet the needs of those customers who have requirements for position. The length is70~470mm.

Operating Guideline

Before use, the user must read the General Description, Safety Considerations and all the contents in Chapter 1 ~3.

Except the General Description, Safety Considerations and all the contents in Chapter 1 ~ 3, the technicians for installation, testing and repair must thoroughly understand all the contents in Chapter4~5.

This Operating Instructions is only applicable to SINO’s KA series integrated linearencoder.

Please read the Safety Considerations below. It is critical information related to safe use of your linearencoder.

Safety Considerations

n To avoid electric shock or fire, the equipment connected to encoder shall be kept from moisture or direct contact with coolingliquids.

n Encoder is a precision measuring instrument. To ensure its normal function, never expose it to external shock orvibration.

Warning:

n To prevent mal-alignment of encoder and avoid electric shock, never open any seal on encoder. There is no part that needs the user’s repair. Please ask the authorized technicians to repair.

Notes :

If finding any smoke or smell from the reading head, please immediately cut off the power supply. As the encoder connects with the numerical display to form a precision measuring instrument, continued use in event of above phenomena might cause fire or electric shock to the numerical display. Please contact LOK SHUN CNC EQUIPMENT LTD. or its dealer. Never try to repair byyourself.

Once the wire between numerical display and encoder is broken or damaged during use, it will cause error to the test data. The user shall take special care on this.

Never try to repair or refit the scale, as it might cause failure, trouble ordamage.

In light of the principle focused on easy installation, use and maintenance by the user, LOK SHUN CNC EQUIPMENT LTD. has developed KA series linear encoder based on the condition of optimized structure and guaranteed precision. With a precision conforming to standard, this product features in good rigidity, straightness, sealing and appearance. The accessories and spare parts are easy to install and repair, resulting in largely reduced installation labors. Please read the following chapters thoroughly, so that you may use this device more easily.

TechnicalParameter

Scaling distance: 0.02 mm (50lines/mm)

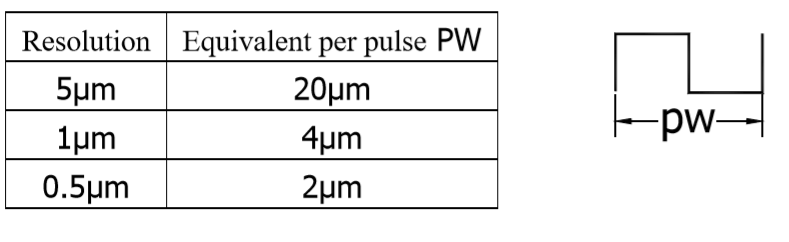

Resolution:5µm、1µm、0.5µm

Precision:3µm、5µm、15µm/m (20±0.1℃)

Measuring range:30~3000mm

Moving speed:High-speedencoder120 m/min (To be customized) Ordinary encoder60m/min

Powersupply: +5V±5%、80mA

Cablelength:Standard3m(Special length available according to the user’s

needs)

Working Temperature:0~45℃

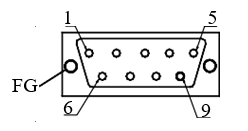

- Applicable to: 9 pin socket EIA-422-A signalOutput.

FG: Shield connected to metal casing.

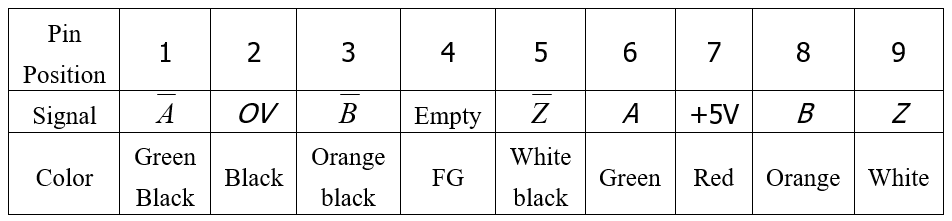

FG: Shield connected to metal casing.

- 10 Signal Wave form

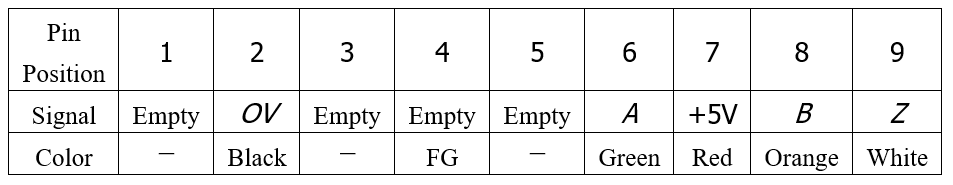

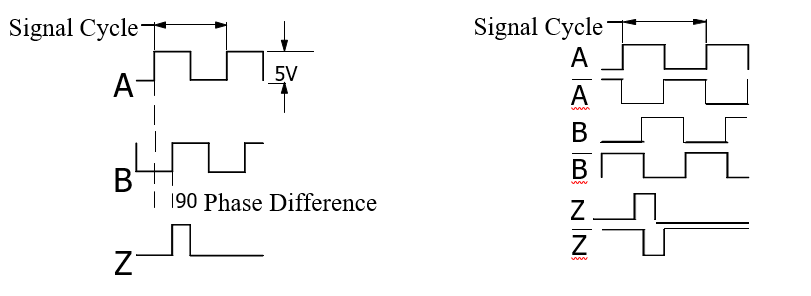

TTLsignalOutput: EIA-422-A signalOutput:

- 11 Encoder Zero Position: 1 every 50mm

- 12 Output pulse signal cycle of encoder PW

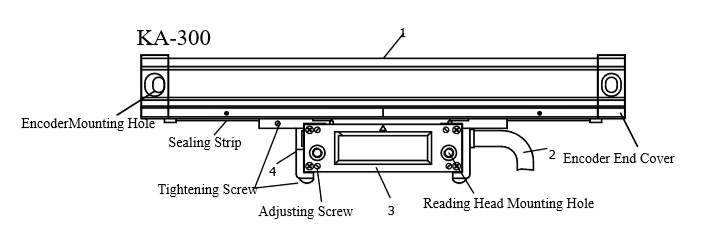

- Scalingbody 2.Cable 3.Readhead 4. Connection plate fixing the readinghead

3. Optional Parts

To install and use the encoder normally under different conditions, we have designed the following spare parts:

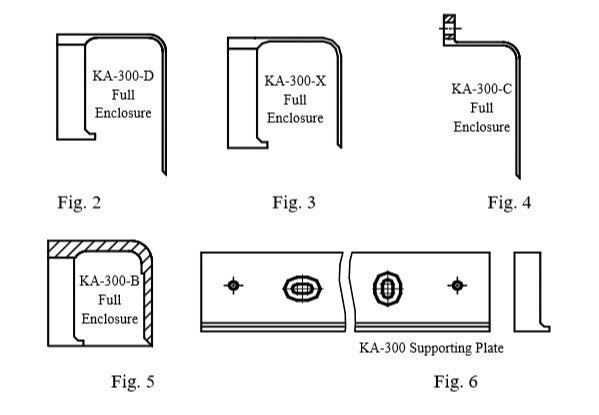

KA-300:

محصولات قابل اتصال به این سنسور

جهت اطلاعات بیشتر مقاله ی زیر پیشنهاد میشود

نقد و بررسیها

هیچ دیدگاهی برای این محصول نوشته نشده است.